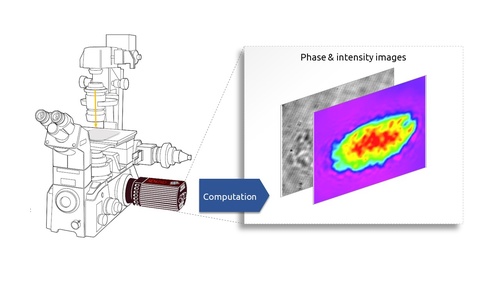

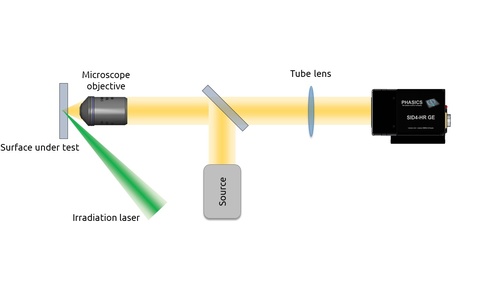

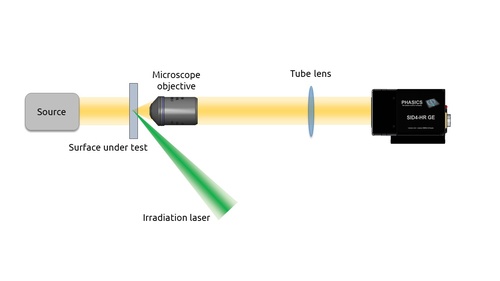

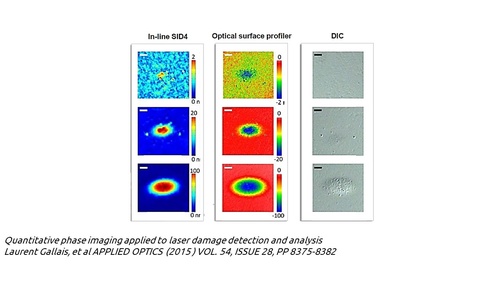

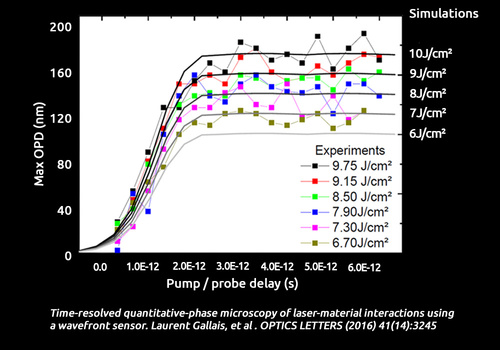

The Phasics SID4 quantitative phase imaging camera is coupled to a classical bright field microscope. A reference measurement is acquired before irradiation and the evolution of the optical path difference (OPD) is monitored during irradiation of the sample.

Advantages

Time resolved

- Single shot

- Well-suited for femtosecond sources

- Pump-probe compatible

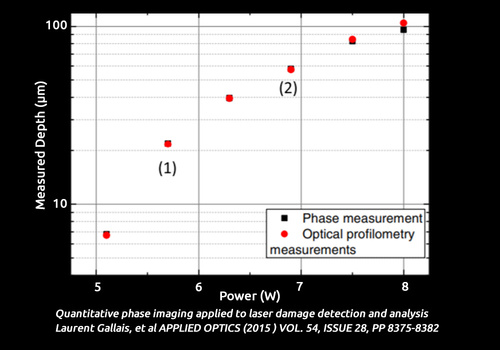

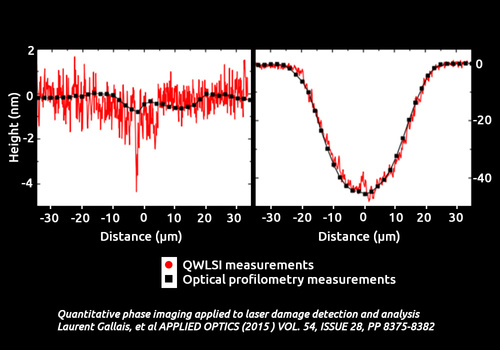

Quantitative measurement

- Nanometric sensitivity

- High dynamic range

- High resolution

Versatile

- On-line and off-line

- Plug & play camera

- Any experimental setup